Why Some 3D Printing Filament Comes Pre-tangled from the Factory

If you have a 3D printer and have bought less-than-premium filament, the following might be a familiar sight:

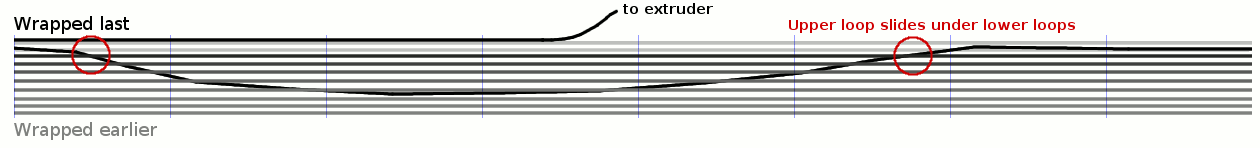

What has happened here is that somehow, a deeper-lying loop of filament in the coil has managed to cross a higher-lying loop. As the filament is pulled from the spool, the deeper loop is dragged along and although it will generally untangle by itself, sometimes it doesn't and you end up with a true knot that jams the feed and causes your nozzle to run dry while the extruder grinds the jammed filament and clogs its feeder gear. This is terribly annoying because not only is your print ruined, you need to disassemble the extruder to clean it and you also need to ensure the coil is properly untangled.

Why does tangling occur, part 1: user error

At first sight the above photo is impossible because if the filament was wrapped according to the laws of physics and topology, then the later loops must always be above the earlier loops, right? Yes, but only if the already wrapped filament has never moved. The common explanation for this kind of tangle is user error, and indeed this is also the most common cause of this kind of filament jam. The error is allowing the filament to slack around the spool in any way. This can happen when:

- simply letting go of the end of the filament while handling the spool,

- letting the spool spin freely on its holder,

- pushing back the filament far enough into the feeding tube without keeping the spool tensioned, for instance while loading or unloading.

If any of the above happens, the filament will partially unwrap in a messy way and will be re-wrapped in some random configuration. It is possible that during this re-wrapping, loops that will be consumed first become clamped underneath loops that will be consumed later. This causes multiple crossing points that can become a fatal kink as shown in the introductory photo when the clamped loop cannot be pulled from underneath the other loops.

There are two lessons to be learnt: one, always keep the filament on the spool under tension. Two, never quickly re-wrap a spool if it has partially unwrapped, and hope it will be all right: it probably won't. If at any point you hear the dreaded slithering sound of filament slacking on the spool and it has been partially unwrapped, continue unwrapping a good amount from the spool until you are back at the tightly wrapped loops, then carefully re-wrap it. (Remember: most filaments are hygroscopic and you should never grab it with sweaty hands, use gloves.)

This is one of the reasons why I frown upon spool holders that try to minimise friction by adding ball bearings etcetera. Doing this greatly increases the risk that the spool will continue turning forward while (un)loading it, during a retraction, or after a fast extrusion, thanks to good old inertia (or rather angular momentum for the nitpickers). A good spool holder must have some friction so the spool will never keep turning on its own. If your printer cannot even overcome that little bit of friction, then you probably have a high-friction zone elsewhere in your filament path that must be eliminated.

Why does tangling occur, part 2: manufacturing error

Still, the spool in the above photo was nearly new and had never turned backwards, it had never spontaneously unwrapped and I never did anything dodgy to it. Yet, like some other spools I have, it managed to jam. It was factory pre-tangled! It also produced the typical sound of filament loops shifting around during printing. I never hear that sound or have such jams with good brands of filament, like rigid.ink. They obviously know how to wrap filament properly. But how then can filament be wrapped improperly?

The most straightforward explanation is that someone in the factory also let go of the end of the spool when it came out of the wrapping machine, and then shoddily re-wrapped it. This would mean however that the filament should become tangled during one of the first prints, which was not the case for my spool. Something more fundamental must have been wrong with it.

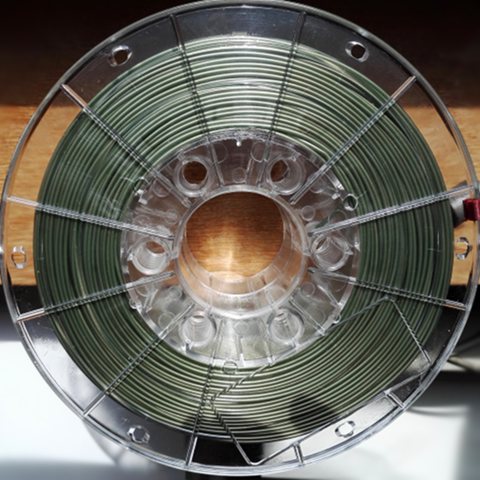

The upside of this particular spool is that it has a transparent holder. Although I always had the suspicion that these tangles originated from filament loops near the flanges of the spool, I could now actually see that this is indeed most likely where the problem resides. By the way, this is brass PETG from the Dutch brand ‘Real’. Material-wise it is very nice, but the wrapping quality will make me think twice before buying more from them.

If you look carefully, you'll see some suspicious things in that photo, especially when zooming in. There seem to be some loops creeping under other loops in both directions, so it is not just due to regular wrapping.

The plot thickened when I was unwinding this entire spool to transfer it to another one. As the following photo shows, the filament is not wound evenly around the spool. At this point, much more filament was wrapped at the centre than at the sides. What I also noticed was that the filament made the most noises when unwrapping from these sides, as I had already observed during prints.

Hence my theory of why the filament can end up in such a tangled state, is that the machine (or Chinese sweat-shop worker) winds the filament around the spool in a haphazard manner and lingers around the centre for too long. Only when the target amount of 1 kg is nearing, it becomes important again to even out the overall profile to make the spool look nice when unpackaged. At this point, the machine or worker will start filling the valleys at the sides. Due to the steep slopes it is possible that loops will slip and slide down, causing them to suddenly go from a larger to a smaller diameter, which leads to slack. It is also possible that the winding machine sometimes cannot keep up with the extruder, again causing slack. Slack can lead to the problem discussed above which finally leads to the disaster scenario from the first photo.

Fixing a tangled spool

Knowing why the spool is tangled does not help much for your ruined print. The goal is to prevent it from happening again. How? There are a few strategies:

- Dunk the spool in the bin and buy a new one from a brand that does not skimp on their wrapping machines.

- Before printing, unwrap enough of the filament for the print and re-wrap it cleanly.

- Before printing, unwrap and cut off the right amount of filament for the print, and wrap it around a mini spool.

- Unwrap the entire spool and re-wrap it around an empty spool.

The first option is easiest but expensive and time-consuming. The next two options of unwrapping part of the spool are only practical for small prints. Therefore, re-wrapping the entire spool in one session is the best solution overall.

If there is one thing I have learnt from my first attempts, it is that simply unrolling more than just a few metres of the spool on the floor and then trying to re-wrap it, is a sure road to total insanity. Doing it with an entire spool would be utter madness. The filament will try to resume its coiled shape, and unless you re-wrap it with exactly the right moves to reconstruct the same coil shape with the same amount of torsion in the filament, it will start turning around in mid-air and form tangles and knots. Untangling those is horribly frustrating. To make things worse, you are likely to rub the filament against various surfaces which will cause it to become statically charged and attract dust. I have seen dust particles orbiting the strand of filament during my first attempt. It was cool to look at, but from a purely objective standpoint, it sucked.

The only sane way to re-wrap the spool is to transfer the filament to another spool and instantly wrap it correctly. It is a bit of overkill because the tangling problems usually only occur in the outer parts of the spool, therefore in theory a partial unwrap is a better option. However, you never know how deep the tangled rabbit-hole goes, therefore going all the way is the only way to be sure.

Re-wrapping, the ideal way

Theoretically, the best way to rewrap the spool is to build a rig with the following features:

- one spool holder with controllable friction and a locking mechanism,

- another spool holder driven by a motor with speed control (possibly controlled with a foot pedal),

- a guide mechanism for the filament in between the two spools.

Extra luxury would be some fancy controller that can completely automate the process of re-wrapping, but face it: unless you're a masochist, you'll only be doing this a few times and then decide to never buy filament from that brand again. Eventually you'll settle for a brand that has properly wrapped spools. For a hobbyist like me, spending inordinate amounts of time and work on a fancy spool re-wrapper machine would be quite a bit of a display of poor judgment.

Re-wrapping, the practical way

Hence I grabbed the nearest objects I could find that approximated this ideal setup, and those proved to be:

- my shoes,

- a can of 3DLac (not because of the contents, it just had the right diameter),

- a piece of wood,

- some gluing clamps (one of which 3D printed),

- duct tape (of course),

- a filament filter (which I normally fit at the entrance of the filament guide tubes).

Yes, it looks ridiculous but it only took me 5 minutes to set up and does the job just fine. Of course it was me who had to do this job, and it was boring. It took 90 minutes, which means that when considering normal wages, this re-wrapped spool became more expensive than the most expensive spool I have ever bought.

The duct tape was used to add friction to the wooden bar. Next to being a support for the spray can axle, the shoes came in handy during breaks to clamp the half-wrapped spool because when left alone it would tend to spontaneously unwrap, which has been proven to be a Bad Thing™ in the start of this article. The filament filter served as the guide device and also helped to add some extra friction which I could control by turning it and changing the angle between incoming and outgoing filament.

The main thing to watch for while re-wrapping is to avoid the uneven kind of wrapping as shown earlier. You must keep slowly zig-zagging from left to right. Ideally every loop you make should perfectly hug the previous loop. In practice however you'll make it a lot messier than that, but even then you should keep on ensuring that the profile of the entire coil is more or less flat at all times. If there is any trace of a valley, fill it immediately instead of letting it grow into a canyon. Pay extra attention to the sides and don't make the same mistake as that machine or sweatshop worker. Make sure the sides are properly filled before moving away from them again.

Whatever method you use to re-wrap the filament, do not handle the bare filament with your sweaty hands. Most filaments are hygroscopic, and coating them with sweat is a sure road to ugly or failed prints. Even if the filament does not suffer from humidity, your sweat contains other substances that do not belong in a 3D print. This is the main reason why I used the filament filter as a guide instead of just my hands. The fact that it removes dust is a nice plus.

Once the filament has been re-wrapped, the whole spool should be heated in an oven for several hours at about 10°C below the glass transition temperature of the filament. This will release the stresses in the plastic and make it assume the shape of the new spool. If you don't do this, then the filament could unwrap wildly if you ever let go if it. Moreover, consider the fact that you have wrapped filament from the largest radius from the old spool, onto the smallest radius of the new spool. That bit of filament will want to return to its large radius shape, therefore the spool is likely to start spinning spontaneously and unwind as you are nearing its end. As an added bonus, heating the filament for a few hours will help to remove that bit of humidity you might have added to it during the whole rewrap procedure.

Conclusion

I think the morale of this story is pretty clear. First of all, treat your filament spools correctly and never allow the filament to slack and unwind. Next, if you try to save money on filament, you'll pay for it anyway in another way, either in the form of your time, money, or just your sanity. And you might have to re-purpose your shoes.

It does pay off to spend that little extra on quality filament, unless you print in such large volumes that the investment of building an automated re-spooling machine will be returned by the savings on cheap spools. For the average hobbyist like me, simply buying a better spool is the more profitable investment. One of my favourites is was rigid.ink, which has never produced a tangle or a clogged nozzle so far, and the filament is of high quality. I'm sure there are other brands out there that offer the same quality but if you live in or near the UK, be sure to check them out. And no, they did not pay me for this article (unfortunately). (Update 2025: unfortunately rigid.ink no longer sells filament.)